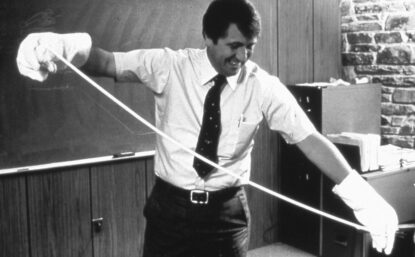

Robert W. Gore

By literally stretching materials science to the limit, Gore invented Gore-Tex, a lightweight, waterproof fabric made from the expanded form of the polymer PTFE.

During a series of failed experiments in 1969, Robert Gore became frustrated and gave a hard yank to a heated rod of the polymer polytetrafluoroethylene (PTFE). The result revolutionized a range of fields from clothing to defense to medicine, and would make his company a household name.

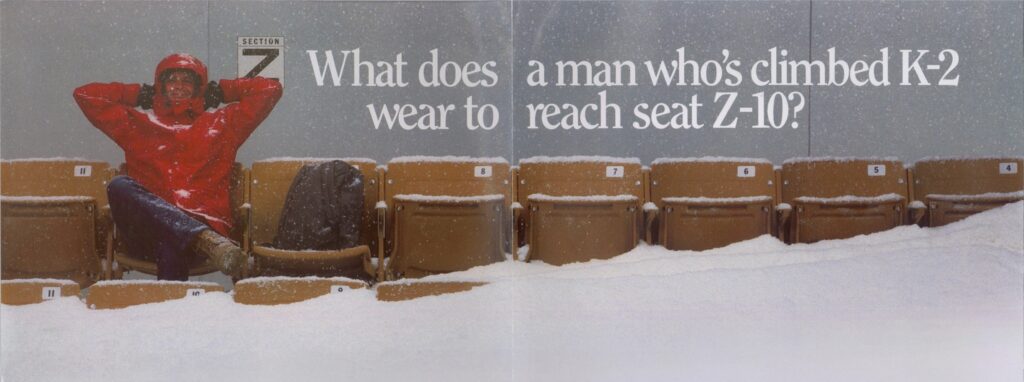

Bob Gore (1937–2020) discovered that PTFE could be transformed into an entirely new physical state. His discovery, known as expanded PTFE, or ePTFE, led to a new direction in materials science and resulted in such well-known products as Gore-Tex fabric and ELIXIR guitar strings. Waterproof, windproof, and breathable, Gore-Tex fabric has revolutionized performance outerwear for outdoor enthusiasts, and ELIXIR strings are widely considered the pioneer in coated guitar-string technology.

Early Life

Gore was born in Salt Lake City, Utah, the first of five children. His father, Wilbert (Bill) Gore, a chemical engineer, entered the DuPont workforce during World War II at its Remington Arms plant in Ilion, New York. From there Bill moved to other DuPont facilities on the East Coast before ultimately transferring to DuPont’s Experimental Station in Delaware.

While still in transition, he purchased land in Newark, Delaware, and started building a house with help from his eldest son and the rest of the family. They spent weekends in Newark, living in a tent while construction progressed. Once Bill officially transferred to Delaware, they lived at a friend’s house until their basement garage was completed, at which time they moved in.

As rooms were added, the family eventually occupied the rest of the house. After this somewhat unusual start Bob Gore led a rather ordinary teenage life, playing trombone, participating in athletics, and serving in student government.

Early Experiments

Bill often experimented in their basement with DuPont materials, either exploring new ideas or finding ways to use them around the house. This independent entrepreneurial bent was permitted among employees of the day since the company viewed itself as an innovator of groundbreaking new materials like neoprene, fluorocarbon refrigerants, nylon, and PTFE. (PTFE, better known as Teflon, was discovered by DuPont scientist Roy J. Plunkett in 1938.) Bob’s father was personally excited about exploiting further applications of PTFE due to its unusual combination of physical, electrical, and chemical properties.

The Birth of W. L. Gore and Associates

Bob enrolled at the University of Delaware in its highly ranked chemical-engineering department. In 1957, just a sophomore in college, he solved a difficult technical problem that his father faced while trying to use PTFE to insulate multiple copper conductors and fashion them into ribbon cable, a product that was finding increasing application in the burgeoning computer industry.

Bob suggested a successful process, and the resulting product, named MULTI-TET cable, gave his parents the confidence to found W. L. Gore and Associates in 1958. Bob’s idea led to the company’s first patent, for which he was listed as the inventor. The company operated in the basement for two years and employed a number of family members, including Bob’s mother, Genevieve (Vieve), who oversaw finances and administration.

In 1960 a large order of MULTI-TET ribbon cable from the Denver Water Company forced the family business to add production capacity, and so Bill and Vieve built a manufacturing plant a short distance away from the house. That facility now serves as the firm’s corporate headquarters. MULTI-TET ribbon cable continued to grow into new applications and, along with other products like TETRA-ETCH and pipe thread tape, helped carry the young company financially into the 1970s.

The Discovery of ePTFE

In 1962 Bob completed a doctorate in chemical engineering at the University of Minnesota. Already a board member of W. L. Gore and Associates, he signed on as an associate in 1963. In 1967 he became the company’s technical and research leader. The big research challenge in the late 1960s was to develop products beyond wire and cable for computing and defense. Trends in electronics at that time made it clear that miniature integrated circuits were the wave of the future and that less cable would be needed as computers became smaller.

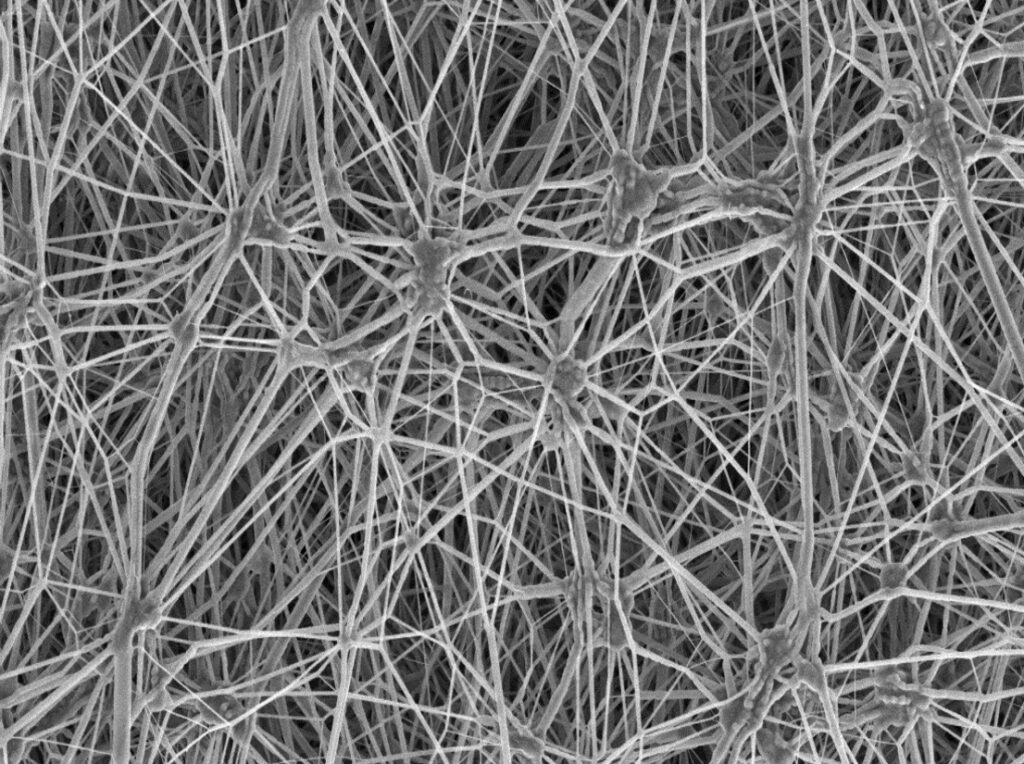

One night in October 1969 Gore was researching a new process for stretching extruded PTFE into pipe-thread tape when he discovered that the polymer could be “expanded.” The discovery followed a series of unsuccessful experiments in which he was attempting to stretch heated rods of PTFE by about 10%. As it turned out, the right conditions for stretching PTFE were counterintuitive. Instead of slowly stretching the heated material he applied a sudden, accelerating yank that unexpectedly caused it to stretch about 800%, which resulted in the transformation of solid PTFE into a microporous structure that was about 70% air.

Soon after, the company was producing a wide range of forms of ePTFE, including fibers, tubes, membranes, and custom shapes. Numerous other products grew from ePTFE, among them new electrical cables, industrial filters, medical implants, textiles woven from ePTFE fiber for space exploration, and laminated fabrics for outdoor activities, emergency response, and defense. The company has grown globally through these products.

The W. L. Gore Work Culture

In 1976 Gore was named president and CEO of W. L. Gore and Associates. In 1986, after his father’s death, he became chairman of the board. He continued his father’s passion for sustaining the Gore company culture, which eschewed a traditional hierarchical management structure and valued individual initiative and ingenuity, ensuring that the company maintained a unique and fulfilling work environment.

He undertook many strategic initiatives as CEO, improving coordination of the firm’s decentralized businesses, promoting operational excellence, and implementing rigorous concept statements and fitness-for-use standards for all products. During his tenure the enterprise maintained its focus on product development through leadership in fluoropolymers, especially ePTFE. In 2000 Gore stepped down as president and CEO, but continued to serve as chairman of the board until 2016.

Recognition

He secured nine patents for his work with fluoropolymers and was elected to the National Academy of Engineering for his technical achievements. He received the 2005 Society for Chemical Industry’s Perkin Medal, the highest award in the United States designated for an industrial chemist, and the 2003 Winthrop-Sears Medal, from The Chemists’ Club and the Chemical Heritage Foundation, now the Science History Institute. Gore was inducted into the National Inventors Hall of Fame in 2006.